Sales hotline

Sales hotline

Home >> Products >> Organic intermediate

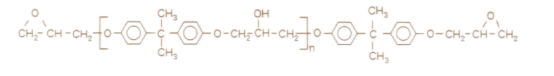

BE Series is made of Bisphenol A and Epichlorohydrin for general applications.

Following is its chemical formula:

It can be used in paint, adhesive, civil construction engineering, electrical and electronic insulator.

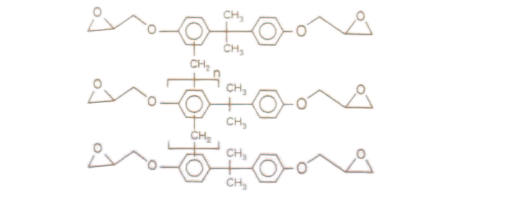

BNE Series,is accomplished by the reaction of epichlorohydrin and bispheno-A-fomaldehyde novolac.

Following is its chemical formula:

BEB Series, brominated epoxy resins,is made of Tetrabromobisphenol A,

Bisphenol A and Epichlorohydrin. Owing to its good flame-resistance,

BEB series have been widely adopted in electronic field, such as copper clad laminate etc.

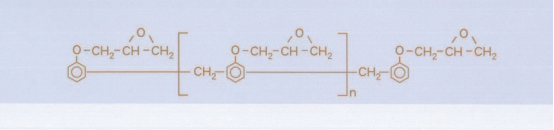

PNE Series is made of special grade Phenol Novolac Epoxy Resin.

Following is its chemical formula:

Because it has more epoxy rings, its heat-resistance,chemical-resistance, adhesiveness are all better than Bisphenol A Epoxy Resin,and are widely used in high temperature adhesive, print circuit board, paint etc.

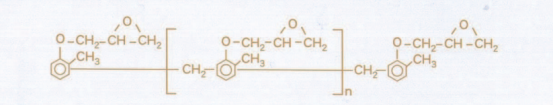

CNE Series is made of special O-Cresol Novolac Epoxy Resin.Following is its chemical formula:

Because It Also Has More Epoxy Tings and Is Good for Heat Resistance, Chemical-Resistance and Adhesive. It Can Also Be Used in Producing Epoxy Molding Compound for Electronic Encapsulation.

We Are Equipped with Modern R&d and Quality Control Facilities, Such as Electrical Microscope,Thermal Heat Analyzers, Optical Analyzers and Chromatography to Do the Service and Ensure Each Item Meet Iso Standards. We Provides Quality Assurance to Our Customers.

Epoxy Resin Test Methods:

· EEW: with HBr/ glacial acetic acid.

· Solution Viscosity: 40% in butyl carbitol solution, Gardner-Holdt Method.

·Softerning Point: Ring & Ball Method

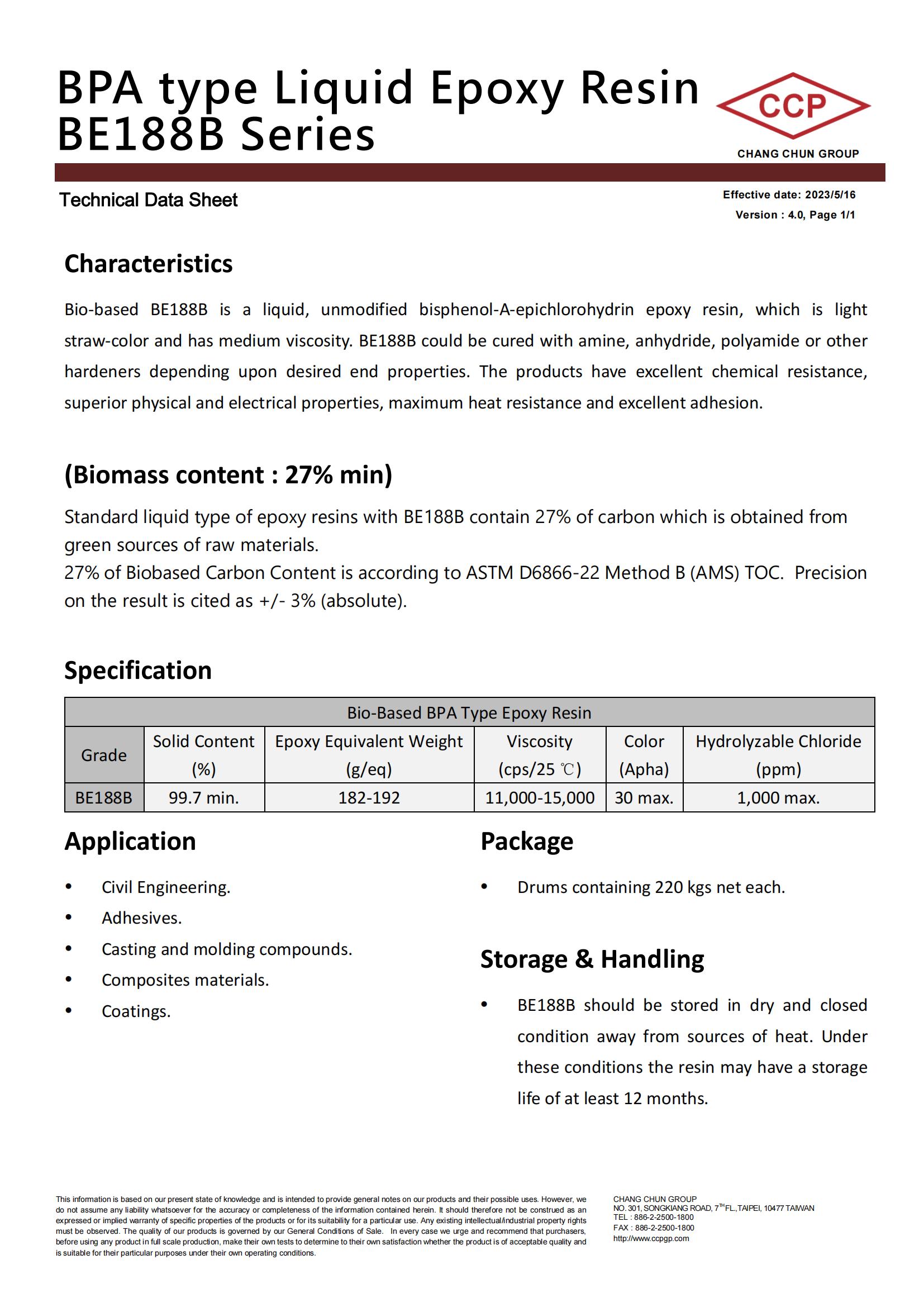

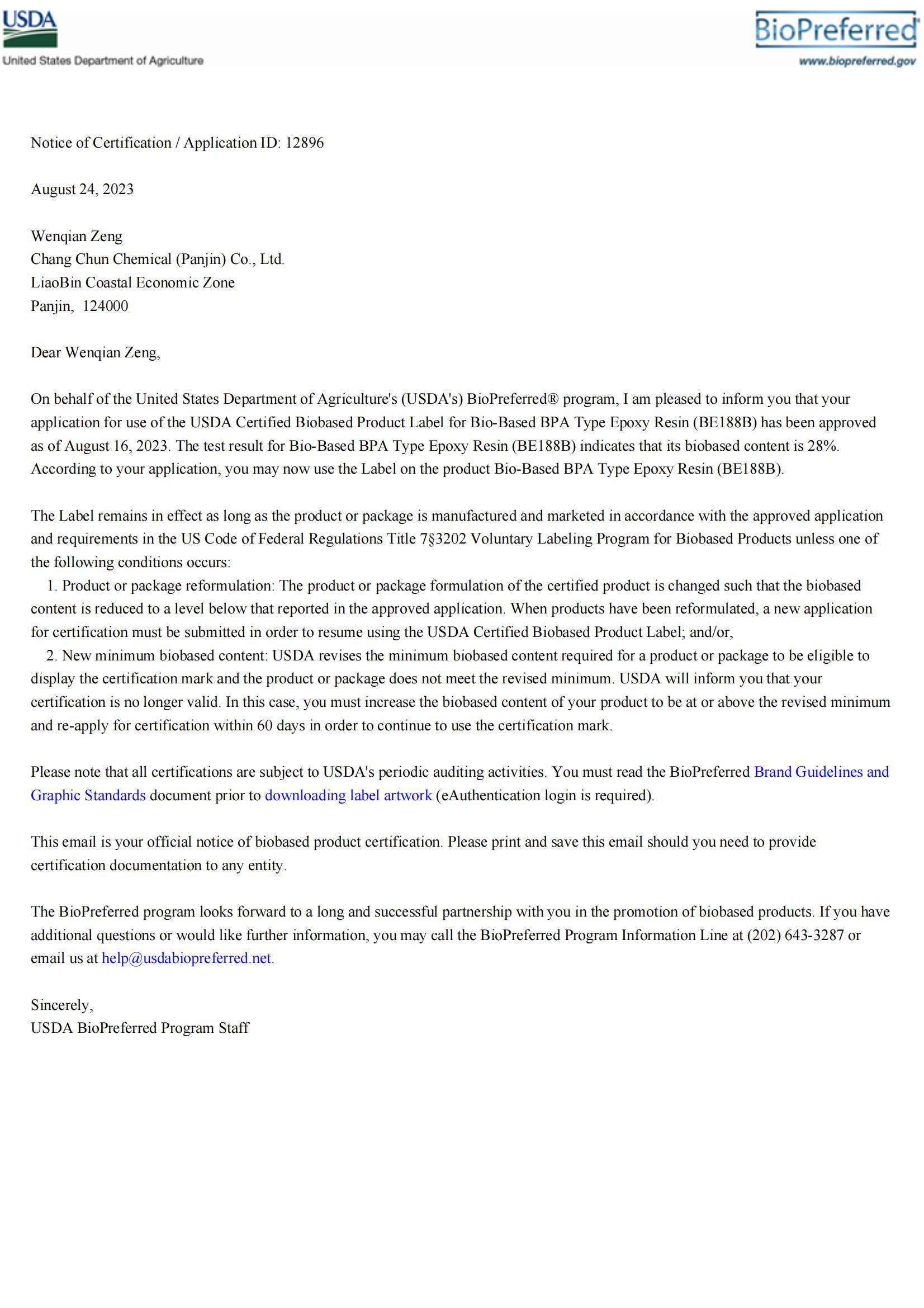

1.1 Bisphenol A Epoxy Resin

Trade Name | BE114 | BE186 | BE186EL | BE188 | BE188EL | BE188LV |

EEW(g/eq) | 195-206 | 180-190 | 182-192 | |||

Viscosity(cps,25℃) | 500-800 | 7000-10000 | 11000-15000 | 10000-12000 | ||

| HyCl(ppm) | ≦1000 | ≦1000 | ≦300 | ≦1000 | ≦300 | ≦1000 |

Color | ≦1(Gardner) | ≦30(APHA) | ≦1(Gardner) | |||

Application | Casting,Potting&Encapsulation for electrical Components.Laminating, Impregnation, Adhesive,Civil Engineering | |||||

Package | 220kg drum | 220kg/240kg drum | ||||

Trade Name | BE124A | BE124B | BE124C | BE124D | BE124E |

EEW(g/eq) | 163-206 | 180-184 | 175-182 | 170-176 | 167-175 |

Viscosity(cps,25℃) | 640-750 | 5500-7500 | 2500-4500 | 1000-2000 | 890-1030 |

| HyCl(ppm) | ≦1 | ||||

Color | ≦1500 | ≦1500 | ≦1500 | ≦1500 | ≦1500 |

Application | Casting,Potting&Encapsulation for electrical Components.Laminating, Impregnation, Adhesive,Civil Engineering | ||||

Package | 220kg drum | ||||

1.2 Soild Epoxy Resin

Trade Name | BE501 | BE502 | BE503 | BE504 | BE505 | BE506 | BE507 | BE508 | BE509 |

EEW(g/eq) | 450-550 | 600-650 | 650-700 | 700-740 | 740-780 | 780-850 | 850-980 | 1700-2300 | 2300-3800 |

Viscosity (Gardner,25℃) | F-K | I-M | K-P | N-R | P-S | S-W | T-W | Y-Z2 | Z2-Z5 |

Softening Point(25℃) | 62-78 | 82-92 | 85-95 | 90-98 | 92-100 | 96-107 | 96-107 | 120-130 | 130-140 |

Color(Gardner) | ≦1 | ||||||||

Application | Protective Coating,Linings,Adhesives,Laminating | ||||||||

Package | 25kg PE bag/850kg super sack | ||||||||

1.3 Solution type Epoxy Resin

Trade Name | BE234X85 | BE236X80 | BE504M70 | BE501M80 | BE188M90 |

EEW(g/eq) | 230-270 | 300-335 | 470-530 | 182-192 | |

Viscosity(cps,25℃) | 2000-4500 | 3500-7000 | 300-800 | 5000-10000 | 100-1000 |

Color(Gardner) | 1MAX. | ||||

Solvent | Xylene | Xylene | MEK | MEK | MEK |

Solid Content(%) | 84-86 | 79-81 | 69-71 | 79-81 | 89-91 |

Application | Used on metal,wood,glass,masonry by brushing,spraying,dipping,ect. Pipe and Drum linings,Marine& Protective Coatings | ||||

Package | 220kg drum | ||||

Used on metal,wood,glass,masonry by brushing,spraying,dipping,ect. Pipe and Drum linings,Marine& Protective Coatings

Sales hotline:

Scan and consult wechat customer service

Scan and consult wechat customer service