Sales hotline

Sales hotline

Home >> Products >> Organic intermediate

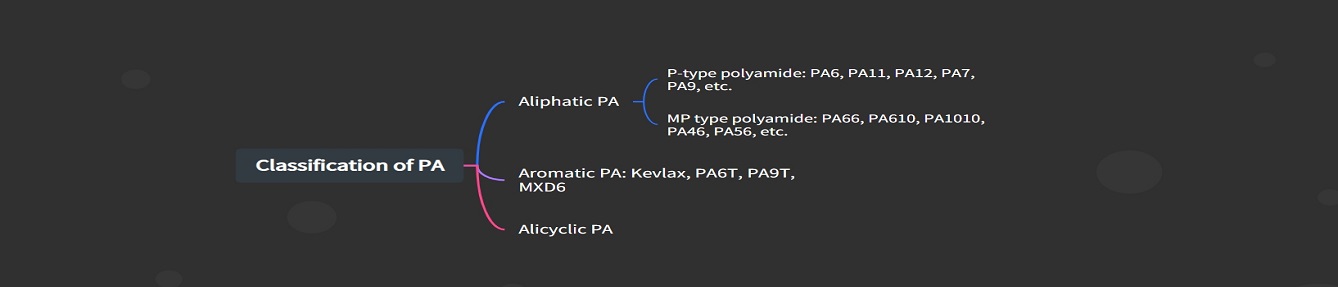

Polym-xylylene adipamide, referred to as mxd6, generally referred to as "nylon mxd6", the resin has higher mechanical strength and modulus than other engineering plastics, and is also a special high-barrier nylon material. Although the barrier properties of mxd6 are slightly worse than those of pvdc and evoh, its barrier properties are not affected by temperature and humidity, which is especially suitable for use in high temperature and humid situations. In today's general trend of barrier packaging and replacing steel with plastic, nylon mxd6 has become one of the eye-catching new plastic varieties.

PA MXD6 nylon material has high strength, high rigidity, high thermal deformation temperature, small thermal expansion coefficient; dimensional stability, low water absorption, small dimensional changes after water absorption, and small changes in mechanical strength; small molding shrinkage, suitable for precision molding processing; It has excellent coating performance, especially suitable for surface coating at high temperatures; it has excellent barrier properties against oxygen, carbon dioxide and other gases. Excellent mechanical and thermal properties, high strength, high modulus and heat resistance, high barrier properties and excellent cooking resistance.

Transparent PA: copolymer or nylon with side groups

Nylon MXD6 is a crystalline polyamide resin, which is synthesized by the condensation of m-xylylenediamine and adipic acid.

| [Basic Physical Properties Table] Pa Mxd6-30cf | ||||

| Basic performance | Specification Level | Exterior Color | Instruction Manual | |

| General Grade | Black | Electromagnetic Shielding, Ultra-High Rigidity | ||

| Feature | Test Methods | Test Conditions | Unit | Test Data |

| Density | ISO 1183 | g/cm 3 | ≥1.32 | |

| Molding shrinkage | ISO294-4 | % | 0.3 | |

| Water Absorption | SO 294 | MPa | ≤0.4 | |

| Bending Strength | SO178 | Mpa | 294 | |

| Melt Index | ISO 1133 | 240℃/5kg | g/10min | ≥13 |

| Flexural Modulus | ISO178 | Mpa | 24564 | |

| Tensile Strength | ISO178 | Mpa | 232.7 | |

| Surface Resistivity | ISO3915-1981 | Q |

3 10 |

|

| Izod Notched Impact Strength | SO179-1 | 3.18 mm | J/m | ≥9.5 |

| Long-Term Temperature Resistance | ISO 75 | 1.80MPa | ℃ | ≥160℃ |

| AASTM D648 | 1.82MPa/12.7mm | |||

| Baking Material Temperature | ISO 75 | ℃ | Drying Temperature: 80 ~ 100°c X 3 ~ 5 Hours | |

| Injection Molding Temperature | SO 75 | ℃ | 280℃~300℃ | |

1. Maintain High Strength and High Rigidity in a Wide Temperature Range.

2. High Thermal Deformation Temperature and Small Thermal Expansion Coefficient.

3. Low Water Absorption, Small Dimensional Change After Water Absorption, And Small Reduction in Mechanical Strength.

4. The Molding Shrinkage Rate Is Very Small, Suitable for Precision Molding Processing.

5. Excellent Coating Properties, Especially Suitable for Surface Coating at High Temperatures.

6. It Also Has Excellent Barrier Properties Against Oxygen, Carbon Dioxide and Other Gases.

Injection Molding of High-Performance Nylon Mxd6 Is Suitable for Selecting a Relatively High Mold Temperature (Mold Surface Temperature 120~140℃). In This Way, If Molding Is Performed at a Mold Temperature of About 80℃, Annealing Treatment (About 1 Hour at 130℃) Is Required. , To Increase the Crystallization Degree of Molded Products to Ensure Strength and Rigidity. In Addition, In the State of Moisture Absorption, Abnormalities Such as Silver Bars (Silver Color) May Appear on the Surface of the Molded Product. It Is Recommended to Perform Hot Air Drying (More Than 12 Hours at 80°c or More Than 4 Hours at 120°c) Before Molding.

MXD6 is used in plastic modification industry

Mxd6 can be compounded with fiberglass, carbon fiber, minerals and/or advanced fillers for materials containing 50-60% fiberglass reinforcement and provides exceptional strength and stiffness.

Even when filled with high levels of fiberglass, its smooth, resin-rich surface creates a high-gloss finish without fiberglass, making it ideal for painting, metallizing or creating naturally reflective enclosures.

1. High fluidity suitable for thin walls

It is a very fluid resin that can easily fill thin walls as thin as 0.5 mm even when the glass fiber content is as high as 60%.

2. Excellent surface finish

The resin-rich flawless surface has a highly polished appearance, even with high fiberglass content.

3. High strength and stiffness

MXD6 is added with 50-60% glass fiber reinforcement, and its tensile strength and flexural strength are comparable to many cast metals.

| Tensile properties comparison | ||

| Material |

Tensile Strength Fracture Mpa |

Tensile modulus GPa |

| MXD6+50% glass fiber | 280 | 20 |

| MXD6+60% glass fiber | 280 | 24 |

| Tin Bronze | 300 | 105 |

| Brass | 250 | 105 |

| Annealed zinc | 150 | 105 |

| Zinc alloy (4%Al, 0.04%Mg) | 280 | 85 |

| Annealed Aluminum (99.6%) | 70 | 69 |

| Duralumin alloy | 190 | 74 |

| Al Ag3 alloy | 140 | 69 |

4. Good dimensional stability

At ambient temperatures, the coefficient of linear expansion (CLTE) of MXD6 fiberglass composites is similar to that of many cast metals and alloys. High reproducibility due to low shrinkage and ability to maintain tight tolerances (length tolerances as low as ±0.05% if properly formed).

In auto parts, many occasions require material products to have high mechanical strength and good oil resistance, and can be used for a long time in the range of 120 to 160°C. Glass fiber-reinforced MXD6 has a heat-resistant temperature of up to 225°C and a high strength retention rate at high temperatures. It can be used in cylinder blocks, cylinder heads, pistons, synchronization gears, etc. of automobile engines. MXD6/PPO alloy has properties such as high temperature resistance, high strength, oil resistance, wear resistance, and good dimensional stability. It can be used for vertical outer panels of automobile bodies, front and rear fenders, wheel covers, and curved surfaces that can hardly be stamped with steel plates. Parts and car chassis

The application of high-barrier packaging materials shows huge development potential. Food packaging is mainly made of PET/MXD6 blends and is used for packaging of wine, beverages, medicines and food.

Soft cushion materials are used for shock-proof packaging of precision instruments, meters and valuables.

1. PET/MXD6 multi-layer bottle

PET resin and MXD6 are used for injection molding, and the bottle formed by stretch blow molding is a multi-layer bottle.

Its structure is PET/MXD6/PET multi-layer bottle with high transparency and excellent gas barrier performance. It can effectively block the penetration of oxygen and the loss of carbon dioxide, and can meet the needs of products with high barrier properties, such as high-concentration juices, teas, Beer, carbonated drinks and functional drinks.

2. PET/MXD6 single mixed bottle

Bottles made by blending PET and MXD6 are single-blended bottles. The single-mix bottle forming process is simple and can be produced using conventional machines without problems such as delamination and peeling.

The single-mix bottle has excellent gas barrier properties, but its appearance is not completely transparent and has a haze similar to a pearl-colored mist. Single-mix bottles with 5% MX nylon added have twice the shelf life of ordinary PET bottles.

3. Film

NYLON-MXD6 is suitable for the production of multi-layer and blend films. Due to its superior barrier properties under high humidity conditions, good processability and superior thermal stability, MXD6 is the best choice for barrier materials for nylon 6 multilayer films, nylon 6 blend films and PET blend films.

Whether it is a multi-layer film or a single-mix film, adding a certain amount of MXD6 can effectively improve the gas barrier properties of the film.

Valve body performance requirements:

1-Resistant to long-term cycle pressure, 16bar

2-Operating temperature: -10~50°C

3-Dimensional stability

4-Good surface quality

MXD6 material matching and modification:

1-Solvay PA MXD6+60% glass fiber reinforcement, tensile strength 280MPa, tensile modulus 24GPa

2-Replacing steel with plastic, cost advantage

3-High thread strength, no need for additional metal inserts

4-MXD6 has excellent dimensional stability

5-Excellent creep resistance and fatigue resistance (below 80°C)

● We have high-quality products, which are directly supplied by the factory to ensure sufficient supply.

● We have professional services, 24 hours online to solve your problems.

● With years of supply experience, we strive to bring value to every customer.

1. Who are we?

We are based in Shandong, China, start from 2020,sell to Domestic Market(45.00%),Western Europe(10.00%),Eastern Asia(10.00%),North America(10.00%),Africa(5.00%),Central America(5.00%),Southeast Asia(5.00%),South America(5.00%),Mid East(5.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

3.Why should you buy from us not from other suppliers?

RD &marketing experience products are exported to Europe, North and South America, the Middle East, Asia Pacific and Africa area, so as to establish a long-term and stable cooperation relationship with customer in the world.

4.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,CPT,DDU,Express Delivery; Accepted Payment Currency:USD,EUR,CNY; Accepted Payment Type: T/T,L/C,D/P D/A,Western Union,Cash; Language Spoken:English,Chinese.

Sales hotline:

Scan and consult wechat customer service

Scan and consult wechat customer service